-

锌在金属消耗排行中占第5位,仅次于铁、铝、铜、锰。锌的用途广泛,锌能与多种有色金属形成合金,是经济建设不可或缺的有色金属[1]。目前,我国的锌合金生产主要采用火法冶炼,在冶炼过程中,为了除去高温状态下锌合金表面生成的氧化物,提高纯度,采用加入大量氯化铵晶体的方法[2]。但是,氯化铵在高温下产生大量白色烟雾,造成严重的环境污染。

氯化铵在100 ℃开始挥发,在328 ℃分解成NH3和HCI,而NH3和HCI在空气中遇冷又重新化合成氯化铵,形成白烟。在氯化铵白烟中既含有颗粒物又含有气态污染物,且烟气中的氯化铵微粒多属于微细颗粒物。何益波等[3-4]采样并测出白烟中的颗粒物平均粒径分布在1 μm以下,重量轻,不易下沉,也不易溶于水。在烟气处理设备中,只有湿式洗涤器能够同时去除烟气中的微细颗粒物和气态污染物[5-7],而作为湿式洗涤器的填料塔具有结构简单、气液接触面积大、运行可靠等明显优势,在烟气脱硫、脱黑等工业废气净化方面发挥了重要作用[8-10]。

通常,传统的填料塔采用顶部喷淋方式,这存在较严重的水雾排放问题[11-15],须在喷淋上部另加除雾器,进而增加了设备投资和能耗。为此,在研究氯化铵微粒净化中,提出了一种底喷式填料塔。烟气先与喷淋液滴接触,进行初净化,较大水滴落入底部水箱,气流携带细水雾,经过填料层过滤,不仅增强了颗粒物净化效果,而且减少水雾排放。同时,润湿的填料表面有利于增强填料的吸附作用,提高二次净化效果。所以,底喷式填料塔既可去除微细颗粒物,又能有效控制水雾排放。

虽然使用纯水作为洗涤液的成本较低,但对微细颗粒物降尘效果较差[16]。为了降低水的表面张力,增加颗粒物的润湿性,有研究[17-18]表明,化学抑尘是一种新颖且效率高的粉尘防治办法。而大部分的抑尘剂均添加了阴离子表面活性剂和非离子表面活性剂[19],表面活性剂的添加会进一步提升对微细颗粒物的脱除效率。

本研究分别选用SDBS(阴离子型)、AEO-9(非离子型)、A-7(非离子型)配制成洗涤液,采用底喷填料塔净化氯化铵微粒,通过对比研究,筛选出较为理想的表面活性剂,不仅提高了微细颗粒物的脱除效率,且废水的生物降解性好,对环境没有二次污染,为细颗粒物的高效净化提供参考。

HTML

-

实验装置如图1所示。主体设备是填料洗涤塔,主要性能参数如下:空塔气速为0.5~1.5 m·s−1,压降为110~500 Pa·m−1,液气比为0.7~2.2 L·m−3,液体喷淋密度为1.8~6.4 m3·(m2·h)−1,填料层高度为600 mm,塔径为250 mm;填料选用塑料矩鞍环,规格为25 mm×12.5 mm×1.2 mm,比表面积为288 m2·m−3,空隙率为0.85,堆积数量为97 680个·m−3,堆积重量为68 kg·m−3,干填料因子为473 m−1;填料塔是吸收的主体设备,采用有机玻璃制作。其他附属实验设备包括模拟烟气发生装置、离心风机、粉尘浓度测定系统等。

实验试剂包括:氯化铵(NH4Cl,分析纯),购于天津市永大化学试剂有限公司;十二烷基苯磺酸钠(SDBS,分析纯),购于南京佳吉化工有限公司;脂肪醇聚氧乙烯醚(AEO-9,化学纯),购于吉林化学工业股份有限公司;椰子油基类低泡表面活性剂(A-7),购于湖南洁宇日化新技术股份有限公司。主要仪器包括远红外封闭电炉(上海力辰邦西仪器科技有限公司)、热线式风速仪(日本KANOMAX公司KA23型)、高压离心通风机(9-26-5A,佛山市南海九州普惠风机有限公司)等。

烟气发生装置放出的白烟是经过高温分解、遇冷又重新化合的氯化铵微粒,通过进气管道进入填料洗涤塔,与自上而下喷淋的洗涤液逆流接触,经过填料层,净化后的气体由风机抽出排放。用水泵将水箱里的洗涤液送入洗涤塔中,与白烟逆流接触后,从洗涤器下端排到水箱中,可循环再使用。填料塔正常工作时,填料层上方的喷嘴不喷雾,每组实验测试结束后,开启阀门,清洗填料层。

填料塔分上填料层和下喷淋区2个部分。含尘烟气在填料洗涤塔内经过2次净化:含尘烟气先经过喷淋洗涤后,再经过填料过滤。对于湿法净化,喷淋塔的净化效率低于填料塔[20],作为串联系统,将低效净化器置于高效净化器之前是合理的。所以,在填料塔中采取底喷方式,这也符合净化原理。

-

配制实验所需浓度的洗涤液,启动实验装置。待装置运行稳定后,由烟气发生装置放出含尘烟气,在进气管道和出气管道的测试点处,使用CCD-304动压平衡烟尘采样仪,等速采样20 min,并同时使用数字压力计,测定装置压降ΔP,采样前后的玻璃纤维滤筒均放入干燥箱至恒重。每组实验测试3次,取平均值。实验室环境温度t=20~25 ℃,湿度H=60%~80%。

实验洗涤液用量为0.2 m3·h−1,烟气流量在95.4 m3·h−1左右,烟气流速为0.5~0.6 m·s−1,填料层高度为0.60 m。通过在水溶液中添加表面活性剂[21]制备不同浓度的洗涤液,设定的浓度和对应的实验条件见表1。

采用滤筒称重法测定除尘效率,采用电子分析天平测玻璃纤维滤筒的质量,通过测定进出口粉尘浓度确定除尘效率。氯化铵微粒的脱除效率由式(1)确定。

式中:η为脱除效率;m1为入口处氯化铵微粒的质量浓度,mg·m−3;m2为出口处氯化铵微粒的质量浓度,mg·m−3。

1.1. 实验装置与试剂

1.2. 实验方法

-

控制氯化铵微粒入口浓度为124.9~194.3 mg·m−3,烟气入口风速为3.4 m·s−1,液气比为2.2 L·m−3,洗涤液为饮用水,6次实验结果如表2所示。

用饮用水作洗涤液时,由表2得出氯化铵微粒的平均脱除效率为41.64%,氯化铵微粒排放浓度均高于70 mg·m−3,超过大气污染物排放标准[22]。在用水脱除氯化铵微粒时,效率低的原因是:氯化铵本是一种极易溶于水的物质,常温常压下,在水中的溶解度达到28.2%,但经过高温分解,遇冷重新化合生成的氯化铵微粒物理化学性质已经发生了变化,其粒径在1 μm以下,不易下沉,也不易溶于水。氯化铵微粒很难被水润湿,并且其周围可能被一层空气膜包围,将其隔绝开来,进一步增加了被水润湿的难度,使得氯化铵溶解度大大降低,导致填料塔洗涤效率不高。

-

为分析不同表面活性剂对氯化铵微粒脱除效果的影响,控制氯化铵微粒入口浓度为124.9~194.3 mg·m−3,烟气入口风速为3.4 m·s−1,液气比为2.2 L·m−3,在洗涤液中分别添加SDBS、AEO-9、A-7作对比实验。各表面活性剂浓度的选取见表3。

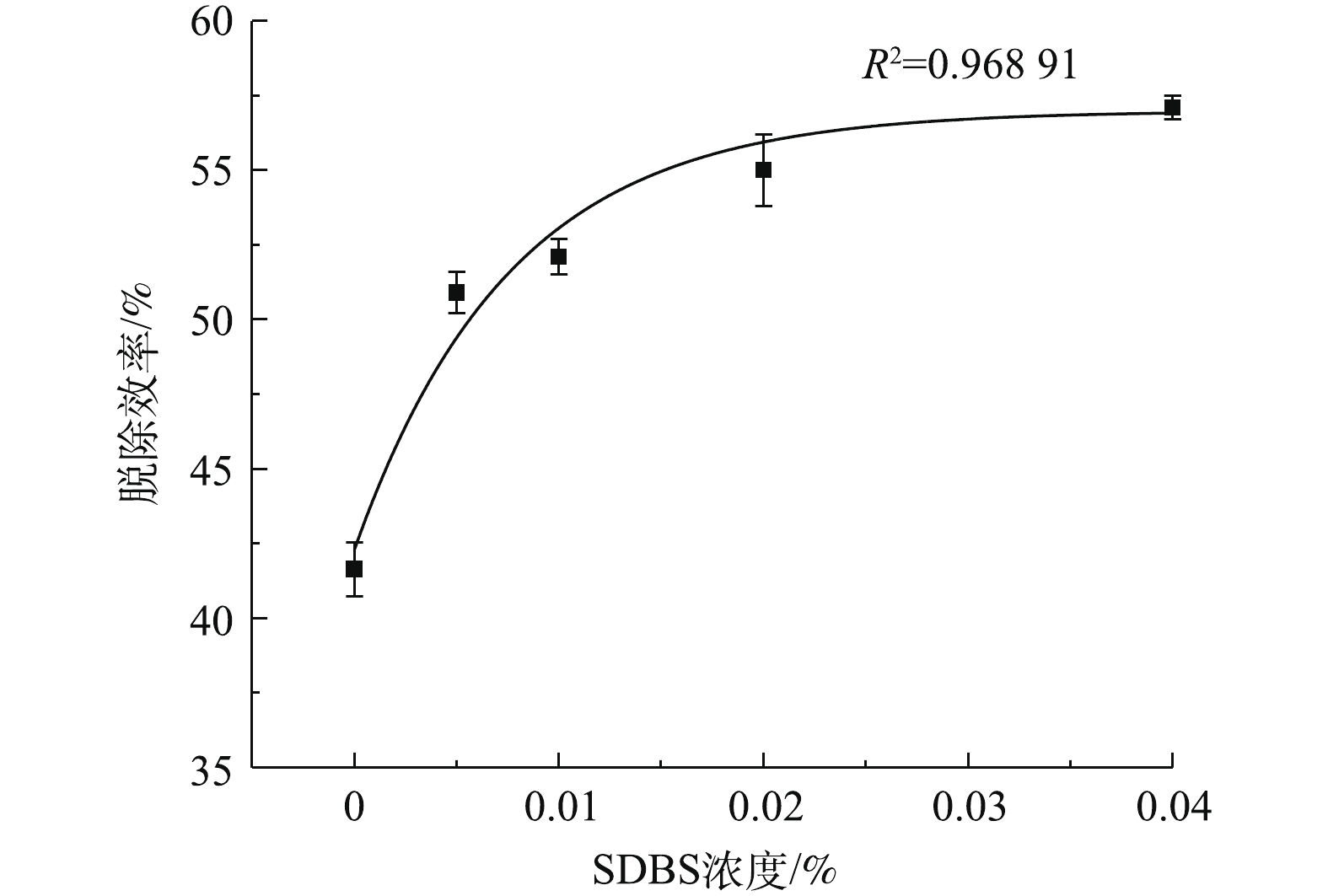

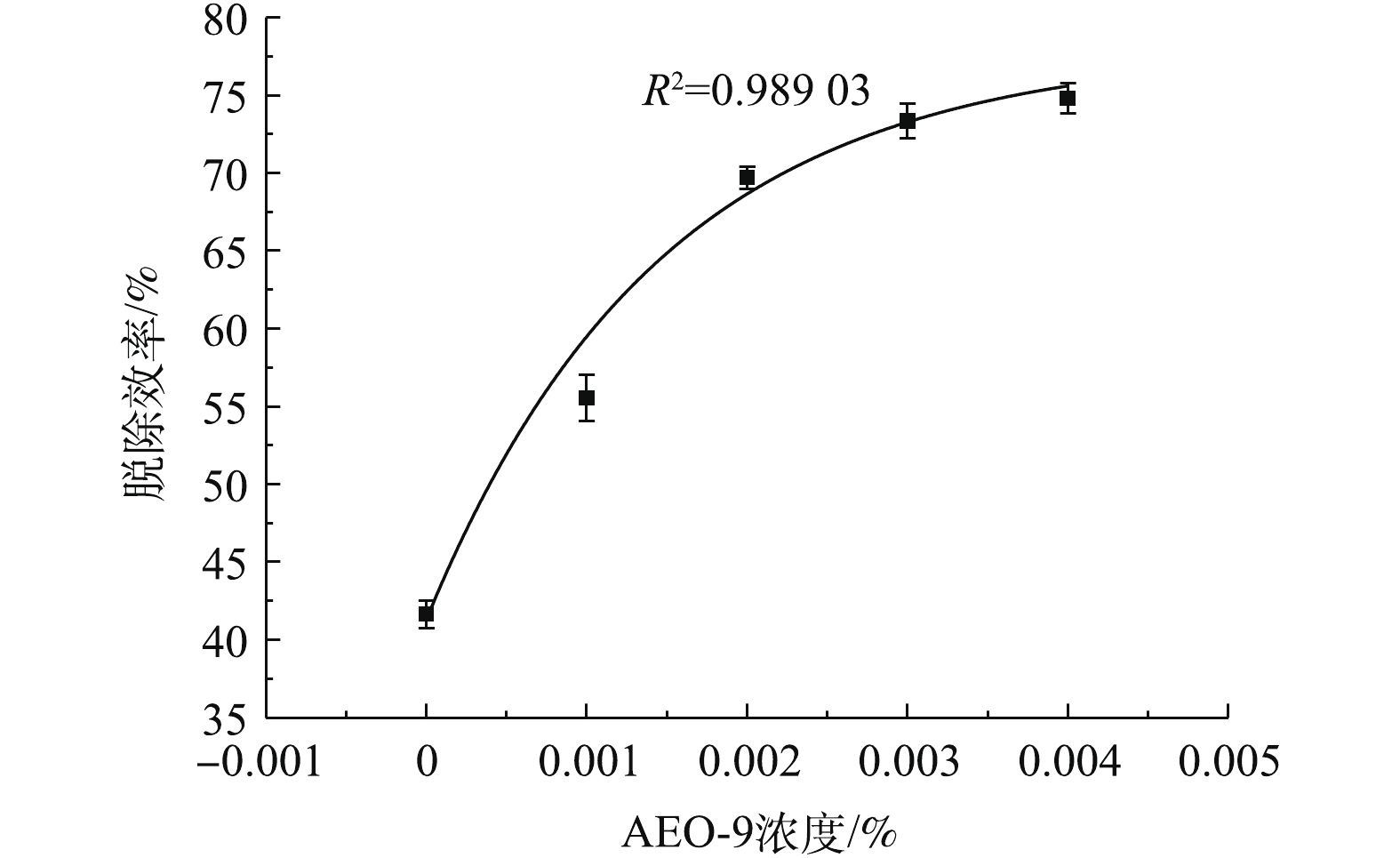

由图2和图3可以看出,添加SDBS和AEO-9表面活性剂的洗涤液对氯化铵微粒的脱除均有提效作用。AEO-9洗涤液对氯化铵微粒的脱除效率优于SDBS洗涤液。当洗涤液中SDBS浓度为0.04%时,脱除效率为57.1%,虽然高于清液的脱除效率,但出口浓度仍未达到排放要求。而当添加AEO-9洗涤液的浓度为0.004%时(比SDBS洗涤液低10倍),氯化铵微粒脱除效率达到74.8%,排放浓度为26.5 mg·m−3,满足排放标准。但研究发现,无论采用SDBS 还是AEO-9,当SDBS洗涤液浓度超过0.04%,AEO-9洗涤液浓度超过0.004%时,会产生较多泡沫,影响系统运行。另外,沉淀池中含SDBS和AEO-9污水须净化后外排,否则会导致水污染。

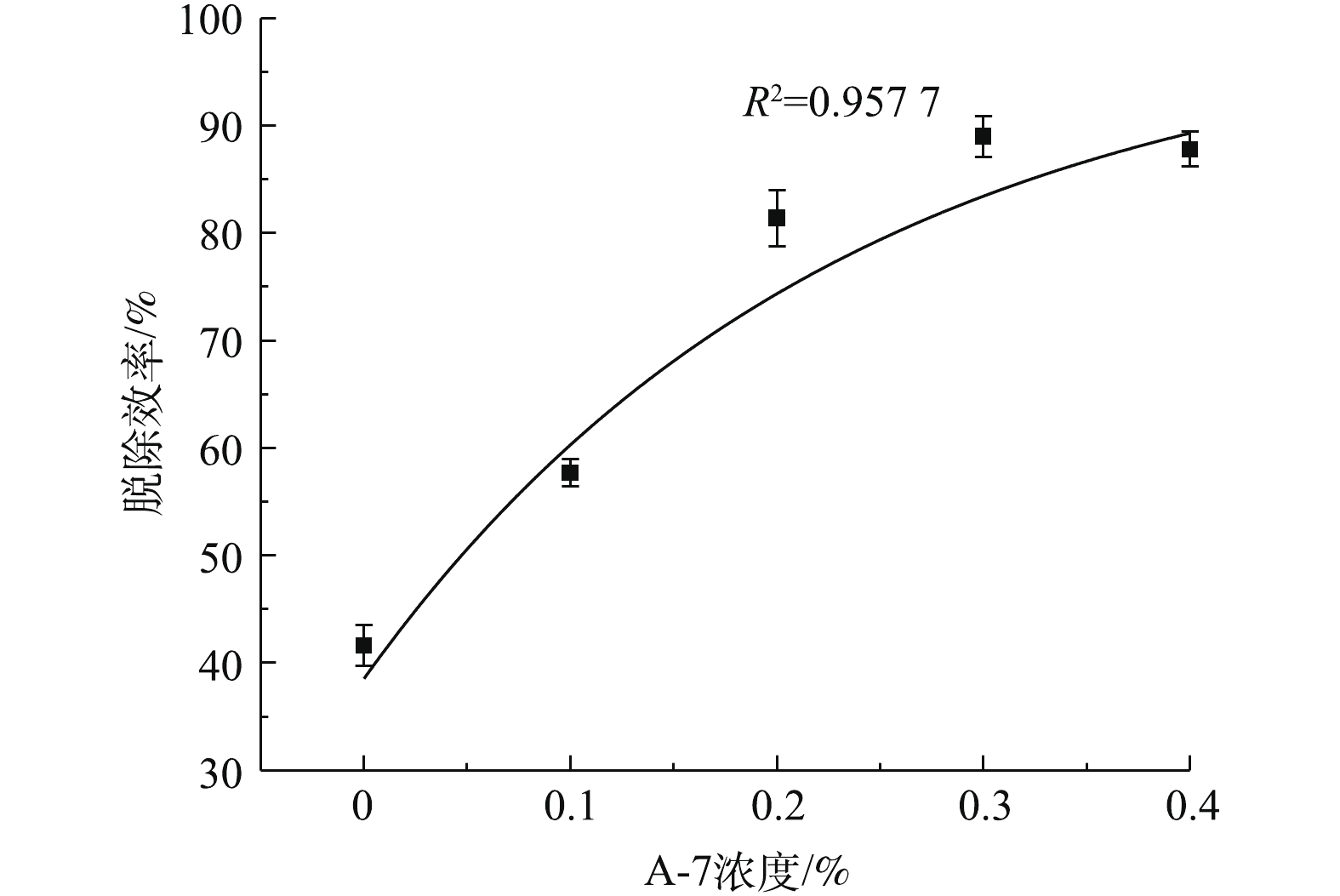

椰子油基表面活性剂可广泛用于生产民用洗洁剂,具有环境友好的特点。因此,为解决SDBS和AEO-9洗涤液多泡和二次水污染问题,对比实验选用了椰子油基类低泡表面活性剂(A-7),实验结果如图4所示。研究发现,采用A-7制备的洗涤液的增效作用明显优于SDBS和AEO-9洗涤液。当浓度为0.3%时,脱除效率达89%,出口浓度仅为15 mg·m−3,远低于标准规定的排放限值。虽然在洗涤液中A-7的添加量远高于SDBS和AEO-9,但在运行中A-7洗涤液产生泡沫很少,且水污染小。对比分析认为,采用A-7表面活性剂制备脱除氯化铵微粒的洗涤液是较合理的选择。

根据图2~图4中的数据,通过指数回归分析发现,回归曲线与实验结果的决定系数R2均大于0.95。这表明3种不同表面活性剂洗涤液的氯化铵微粒脱除效率随表面活性剂浓度的变化关系基本服从指数规律(式(2))。

式中:η为氯化铵微粒脱除效率;ω为表面活性剂的质量分数;A1、A2、k为待定系数(见表3)。

基于式(2),根据洗涤液中表面活性剂的浓度,可预计底喷填料洗涤塔的氯化铵微粒脱除效率。因此,表面活性剂的脱除效率指数模型对工程设计有一定指导作用。

2.1. 饮用水对氯化铵微粒的脱除作用

2.2. 表面活性剂对氯化铵微粒脱除的增效作用

-

1) 将传统填料塔的顶部喷淋方式改为底部喷淋方式,不仅增强了填料塔对细颗粒物的净化作用,而且有助于大幅度削减水雾排放。

2) 饮用水作为洗涤液对粒径小于1 μm的氯化铵微粒的净化作用较弱,填料塔的脱除效率仅在40%左右,出口处氯化铵微粒质量浓度均高于70 mg·m−3。

3) 洗涤液中添加SDBS、AEO-9、A-7表面活性剂,均能提高氯化铵微粒脱除效率。AEO-9的脱除效率高于SDBS。当AEO-9浓度增至0.004%时,脱除效率达74.8%,出口浓度为26.5 mg·m−3,满足排放标准;当采用A-7活性剂配制的洗涤液浓度为0.3%时,对氯化铵微粒的脱除效率高达89%,此时出口浓度仅为15 mg·m−3,远低于标准规定的排放限值。虽然A-7的添加量远高于SDBS和AEO-9,但A-7表面活性剂配制洗涤液的净化效果好、泡沫产出少、环境危害小。因此,A-7是用于配制氯化铵微粒净化洗涤液较为理想的表面活性剂。

DownLoad:

DownLoad: